Capacitor buck LED driver circuit is often used in the drive circuit of small current LED due to its small size, low cost and relatively constant current.

The capacitor buck LED driver circuit uses the capacitive reactance generated by the capacitor at a certain AC number to limit the maximum operating current. For example, at a operating frequency of 50 Hz, a 1 μF capacitor produces a capacitive reactance of approximately 3180 Ω. If an AC voltage of 220 V is applied across the capacitor, the maximum current flowing through the capacitor is approximately 70 mA. But no power is generated on the capacitor, because if the capacitor is an ideal capacitor, the current flowing through the capacitor is the imaginary current, and the work it does is reactive power (the capacitor belongs to the energy storage component).

According to this feature, if a resistive element is connected in series on a 1 μF capacitor, the voltage obtained across the resistive element and the power dissipation it generates are completely dependent on the characteristics of the resistive element.

For example, a 110V/8W bulb is connected in series with a 1uF capacitor and connected to an AC voltage of 220V/50Hz. The bulb is illuminated and emits normal brightness without being burned. Because the 110V/8W bulb requires 8W/110V=72mA. It is consistent with the current limiting characteristics of the 1uF capacitor.

Similarly, a 65V/5W bulb and a 1uF capacitor can be connected in series to a 220V/50Hz AC, and the bulb will be illuminated without being burned. Because the operating current of the 65V/5W bulb is also about 70mA. Therefore, the capacitor buck is actually using the capacitive reactance current limit, and the capacitor acts as a limiting current and dynamically distributing the voltage across the capacitor and the load.

The conventional method of converting AC power to low-voltage DC is to use a transformer to step down and then rectify and filter. If it is limited by factors such as volume and cost, the simplest and most practical method is to use a capacitor buck power supply.

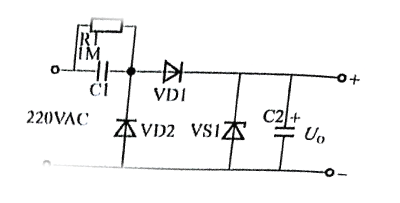

When designing the circuit, the exact value of the load current should be measured first, and then the capacity of the step-down capacitor should be selected. Capacitor buck application circuit diagram, as shown in figure below

Since the current Io supplied to the load through the step-down capacitor C1 is actually the larger the charge/discharge current Ic C1 flowing through C1, the smaller the capacitive reactance Xc is, the larger the charge and discharge current flowing through C1 is. When the load current Io is less than the charge and discharge current of C1, excess current flows through the Zener. If the maximum allowable current Idmax of the Zener diode is less than Ic-Io, it will easily cause the Zener diode to burn out. In order to ensure reliable operation of C1, the withstand voltage selection should be greater than twice the supply voltage. The bleeder resistor R1 must be selected to vent the charge on C1 for the required time.

This article is from Allicdata Electronics Limited