1.The role of the gas sensor.

The device that can sense the change of gas sensing concentration is called gas sensor. Gas sensors are widely used in petroleum, mining, machinery, chemical and other light and heavy industries as well as ordinary families about gas poisoning and fire, detection, alarm and control of accidents such as explosion and air pollution. In industrial production and people's daily life, gas sensors are widely used to detect the leakage of combustible gases and toxic gases, in case of air pollution, explosion, fire, poisoning, etc. There are many kinds of gas sensors , and the most common ones are semiconductor gas sensors.

2.The characteristics of the gas sensor.

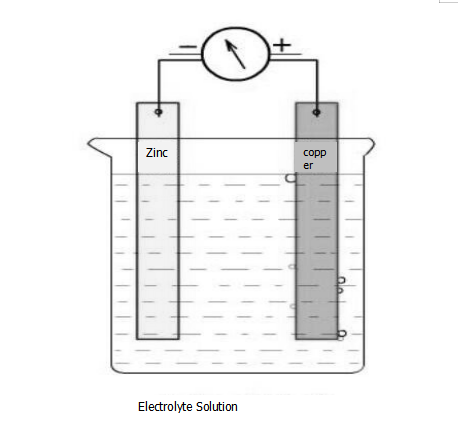

Semiconductor gas sensor is the core of semiconductor gas sensor. It is made of the characteristic that the semiconductor material SnO 2 can adsorb the gas to change its resistance. When the detected gas is adsorbed on its surface, the proportion of conductive electrons in the contact interface of the semiconductor crystallite particles will change, so that the resistance value of the gas sensor will be changed measuring the concentration of the gas changes, so the gas concentration can be converted into the change of the Telecom number. This reaction is reversible and therefore reusable.

In order to speed up the reaction and achieve high sensitivity, it is usually necessary to heat the gas sensor with electric current through the heating wire. The heating temperature varies with the material used by the gas sensor. When the gas sensor starts heating in the clean air, the resistance drops sharply, and the stable value is reached after a few minutes, which is called the passive period stabilization time. When the resistance of the gas sensor is in the stable value, it will change with the adsorption of the detected gas. The variation of resistance depends on the type of semiconductor. The resistance of P-type semiconductor gas sensor increased, and the resistance of N-type semiconductor gas sensor decreased. After the gas sensor is heated, the resistance in the normal air is the static resistance Ro, and the resistance value of the gas sensor is Rx, the ratio of Ro to Rx is called the sensitivity of the gas sensor. When the gas sensor is in contact with the detected gas, the time of its resistance changing from Ro to Rx is called the response time; when the gas is removed, the time of recovery from Rx to Ro is called recovery time.

3.Choose a gas sensor in use.

(1)The sensitivity of the measured gas is high, and the variation of resistance per unit gas concentration is large.

(2) Good selectivity for single or multiple measured gases is less dependent on the temperature of the environment.

(4) Good moisture resistance.

(5) Long life.

To understand their aging mechanisms, they can predict their lifespan.

4.Detect the gas sensor.

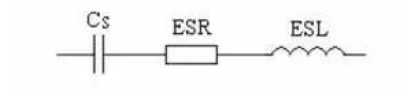

Add voltage to the gas sensor, when the gas sensor is connected to the circuit, the voltmeter pointer should be deflected in the negative direction and go back to zero after a few seconds, and then gradually rise to a stable value, indicating that the gas sensor has reached the preheating time. The ammeter should be indicated within 150mA, with some gas (such as alcohol, liquefied gas and so on) aiming at the gas sensitivity. Probe, use a multimeter to measure the voltage at both ends of Uo.

The gas should change, no change is bad. (the greater the amplitude of the voltmeter is, the better the performance of the gas sensor.)

If you want to know more, our website has product specifications for gas sensors, you can go to ALLICDATA ELECTRONICS LIMITED to get more information

Gas Sensors CCS811B-JOPD500

LOW POWER DIGITAL SENSOR FOR INDAir Quality Sensor I²C